Application of Heavy-Duty Connectors in Wind Power

Under the advocacy of low-carbon, environmentally friendly, and sustainable development, countries worldwide have listed the development of renewable energy as an important goal in successive. In such a case, wind power becomes the optimal target for governments. It is a non-polluting, clean, efficient, low-cost, and renewable resource. In addition, wind power doesn’t require any fuel during power generation, so it won’t produce radiation or pollute the air. With the gradual maturity of wind power technology, wind power will maintain rapid development for a long time.

The heavy-duty connector is a new type of connector widely used in heavy industry and industrial applications. Compared to traditional connectors, it is waterproof, explosion-proof, and convenient for wiring. Due to its firmness and reliability, the heavy-duty connector has gained popularity in wind power turbines. For example, this product provides stable and reliable connections for the control system, pitch control system, yaw system, and wind turbine.

This article will briefly introduce wind turbines and WEIPU‘s heavy-duty connector solutions; keep reading!

Introduction of Wind Turbines

The wind turbine comprises a wind measurement system, pitch control system, convert system, generator cooling system, safety chain system, yaw system, and hydraulic system. On the other hand, this device contains pitch, rotor, controller, yaw drive, generator, and other parts required for reliable and robust connectors. The following is an introduction to the three types of wind turbine systems:

- Yaw System

The yaw system is installed on the upper part of the wind turbine nacelle and adopts the form of an active wind gear drive. This system cooperates with the control system so that the impeller can quickly and smoothly align the wind direction, obtain the maximum wind energy and improve efficiency. At the same time, the yaw system provides the necessary locking torque to ensure the safe operation of the unit.

- Pitch Control System

The pitch control system is located inside the gear of the wind turbine. This device controls the power by changing the angle of blade rotation. For example, when the wind speed surpasses the cut-out wind speed, it helps to stop the blades. Therefore, it is a control and protection device for wind turbines.

On the other hand, according to the actuator, the pitch can divide into a hydraulic pitch system and an electric pitch system. Hydraulic pitch mainly pushes the blade through the hydraulic system by changing the pitch angle of the blade. While the electric pitch system controls the blades individually by the motor. Compared with hydraulic pitch systems, electric pitch systems are favored by many manufacturers due to their compact and simple structure.

- Convert System

The convert system refers to the electric equipment that changes the voltage, frequency, phase, and other characteristics through the converter to meet the standard when the wind turbine generates electricity that does not meet the requirements of the power grid. The converter includes rectification, inversion, AC conversion, DC conversion, and control power switch software.

Why Wind Power Generation Needs Heavy-Duty Connectors

For wind turbines, measures to estimate their value lie in the multiple times of use and ease of use. For example, using some sophisticated elements that are easy to install and maintain can greatly improve the value of the equipment. So, the above systems and some other components all require robust connectors. WEIPU’s heavy-duty connectors are undoubtedly the optimal choice. The following are the advantages of WEIPU Heavy-duty Connectors:

- Durability

The product is made of cast aluminum or flame retardant thermoplastic material to withstand shock and mechanical stress. It is specially designed to meet the requirements of harsh environmental conditions with an I65 protection level. In addition, our product provides effective protection for the equipment in harsh environments such as sand, rain, snow, and heavy pollution.

- Convenience

In many wind power applications, heavy-duty modular connectors allow users to configure the exact interface required for an application in a single connector to reduce the number of interfaces. As a result, this product realizes the modular structure of each functional template conveniently and efficiently.

- High-cost Performance

Rapid assembly can reduce the installation cost in the investment stage. Additionally, the plug-and-play connection method requires no special tools for maintenance so that the maintenance will be convenient and fast.

The advantages above of WEIPU’s heavy-duty connectors fully meet the various needs of onshore and offshore wind turbines, which greatly improves the efficiency of installation and maintenance and prolongs the machine’s service life.

Primary Recommended Products of WEIPU Heavy-duty Connectors

There following are the three primary recommended products for wind turbine applications. The main application areas of these products include the lighting system, yaw system, convert system, etc.

- HA24B-PS-2B standard electrical connection components for Industry 4.0

- HA24B-SF-2L/W standard electrical connection components for Industry 4.0

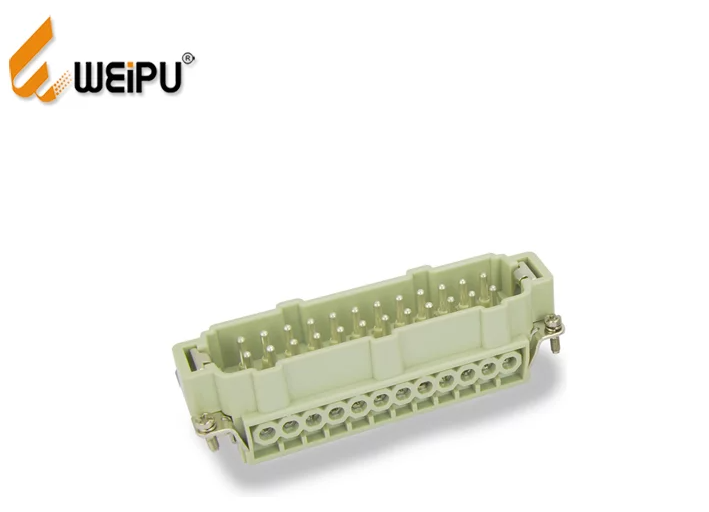

- HE-024-M HA-024-F Male and Female 16A 500V 24+PE Screw termination Connector

Why Choose WEIPU

Since its establishment of 25 years, WEIPU has become one of the largest connector manufacturers in the world. In addition, we specialize in producing industrial connectors and circular connectors to ensure safe and reliable power supply solutions.

On the other hand, we are invited to “National Electrical Appliances Standardization Technical Committees” to draft the national standard GB/T11918-2014 for industrial connectors. WEIPU has a strong R&D capability and can develop various industrial connectors according to customers’ special requirements. For example, our products can meet RoHs, CE, CSA, and UL certifications, so we are your trustworthy partner.

If you need a reliable supplier, contact us.